Email us now

support@heybuildex.comCall us now

+91 92814 46109

Mild Steel (MS) Channels are one of the most widely used structural steel sections in construction, fabrication, and industrial projects. Whether you are building a warehouse, factory shed, residential structure, or doing fabrication work, choosing the right MS channel size and weight is critical for strength, safety, and cost efficiency.

This complete buyer guide explains MS channel sizes, weight chart, types, uses, benefits, buying tips, and FAQs to help customers make informed decisions.

An MS Channel is a C-shaped or U-shaped structural steel section used for load-bearing and support purposes. It is manufactured using mild steel, which offers good strength, weldability, and durability at an affordable cost.

MS channels are commonly used as:

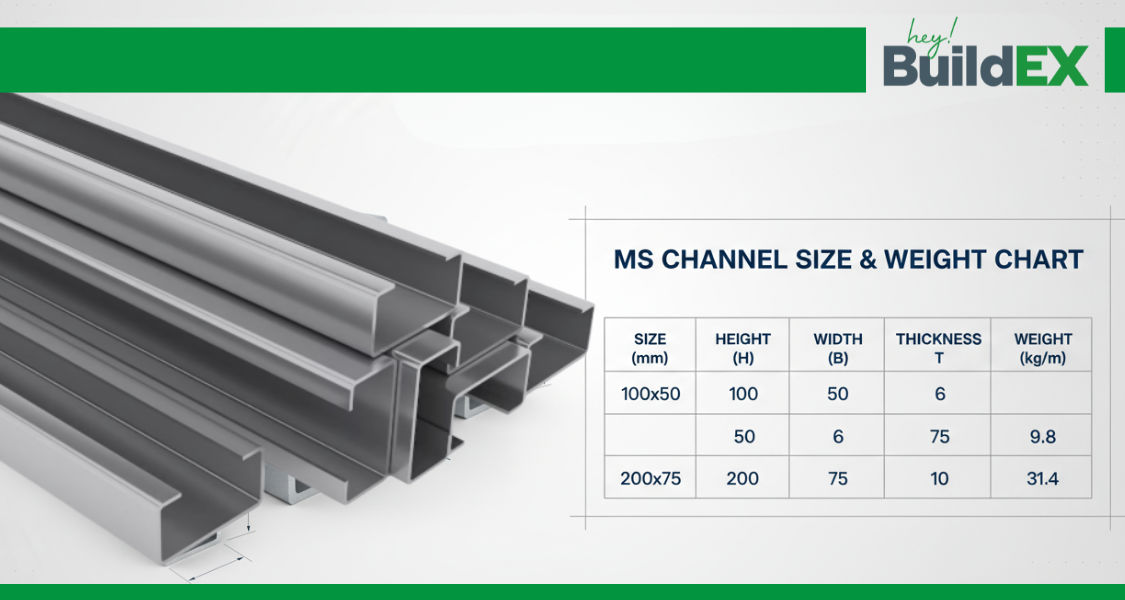

MS Channels are classified based on their depth (height), flange width, and thickness. Selecting the correct size ensures structural safety and cost efficiency.

| Channel Size (mm) | Approx. Weight (kg/m) |

|---|---|

| 75 × 40 | 7.14 |

| 100 × 50 | 9.56 |

| 125 × 65 | 13.10 |

| 150 × 75 | 16.80 |

| 175 × 75 | 19.60 |

| 200 × 75 | 22.40 |

| 250 × 82 | 29.60 |

| 300 × 90 | 36.30 |

| 350 × 100 | 41.50 |

| 400 × 100 | 48.30 |

Note: Weights are approximate and may vary depending on manufacturer and applicable IS standards.

Consider the following factors before purchasing:

For large or critical projects, always consult a qualified structural engineer.

While selecting the right MS channel size and weight is important, sourcing from a reliable supplier ensures quality, compliance, and long-term performance.

HeyBuildEX is a trusted online construction materials platform where customers can buy certified MS channels from reputed brands in all standard sizes with transparent pricing.

Understanding MS channel sizes, weights, and applications helps ensure safe, efficient, and cost-effective construction. Choosing certified products from a reliable supplier like HeyBuildEX guarantees quality, safety, and long-term structural performance.

This guide is designed to help customers make confident purchasing decisions and avoid costly structural mistakes.